Catalina 34 Electrical System Upgrade

By Jim Moe Windseeker

[Now includes changes to the Echo Charger wiring that moved from the switch to the individual banks (Stu October 2009)] NEW wiring diagram by Walt Tunnessen March 2010 VERY IMPORTANT MODIFICATION discussed here on the message board: http://c34.org/bbs/index.php/topic,6225.0.html

If you use an ECHO CHARGER, please be aware of important wiring information that is NOT included in the installation manual, thanks to Maine Sail: http://www.sailnet.com/forums/electrical-systems/72295-xantrex-echo-charger-rant.html

Please Note that this upgrade can also be accomplished while keeping the single 1-2-B switch with a minor change in wiring. Please see the text at the end of this article. The advantage of keeping the 1-2-B switch is that you can use the "B" position of the switch to parallel the batteries for charging and save money by not having to buy an echo charger, duo charger or combiner. Yes, it's a manual operation, but so is starting your engine!!!! And, since the AO goes directly to the house bank, you can even turn the 1-2-B switch OFF with the engine running and not have any problems. Stu, April 2010

You MUST remove the short wire between the alternator and the starter when you make this upgrade to make the 1-2-B switch a "use" switch instead of a "charge" switch. There is a lot of information in the Electrical 101 Topic on the Message Board, see the "101 Topics" sticky.

Bernd of Karista in Florida has provided ANOTHER source for replacement alternators. See the Message Board here: http://c34.org/bbs/index.php/topic,5686.0.html [Stu June 2010] It also notes that the B2 shorepower connection is NOT required with the echo charger.

IMPORTANT FUSE SIZE NOTE: Maine Sail recommends a minimum 200A fuse at the battery banks to avoid nuisance trips. [Oct. 2013] http://c34.org/bbs/index.php/topic,7814.0.html

Contents

Background

The stock Catalina 34 dc power system in earlier boats was designed for minimal house loads and definitely not for extended cruising. Consequently, two similar deep cycle batteries were provided (typically Group 24 or 27) for both house loads and engine starting. This arrangement resulted in several issues for today’s typical loads of refrigeration, lighting, instrumentation, appliances and 115 Volt inverters. Additionally, really only one of the two batteries could safely be used for house loads since the second one always should be reserved for engine starting. This is a common arrangement and typical of many stock sailboats even today.

The stock alternators on most earlier Catalinas are 55 Amp units with internal automotive type regulators. These are designed to replace energy used in starting, support electrical loads while the engine is running and maintain or “float” the battery. They are not designed to, nor will they efficiently, recharge a large, discharged deep cycle battery. Thus even running the engine while cruising or at anchor will not recharge a discharged house battery in any reasonable length of time nor will it provide the electrical energy typically required for extended cruising.

With the original wiring, the battery switch had to be placed on “Both” or a battery isolator installed to charge both batteries with the alternator. Using the battery switch in this manner at times resulted in forgetting it in the “Both” position when the engine was shut down, thus discharging both batteries and having a dead engine. A battery isolator intended to correct this inserted a voltage drop of around 0.7 Volts between the alternator and each battery which effectively prevented the alternator from recharging depleted batteries to more than 60-70% of capacity regardless of how long the charging continued..

The battery cables provided in these boats are very long due to the battery location relative to the battery switch and engine. This, and the small wire size (#4), significantly reduced the current available to the starter. If the battery was partially discharged, particularly in very hot or very cold weather, there often was inadequate current to start the engine.

The solution

The solution to these problems requires several upgrades as follows:

- Replacing the existing pair of similar batteries with a large house load battery bank and an isolated, smaller dedicated engine starting battery.

- Replacing the alternator with a higher current equivalent along with a “smart” regulator designed to more rapidly recharge a discharged house battery.

- Installing an Echo Charge unit or Battery Combiner to automatically charge both house and engine starting batteries from the alternator without incurring the voltage drop of a battery isolator and to avoid requiring the 1-2-BOTH switch to select which bank to charge.

- Installing a “smart” three-stage shore power charger to rapidly recharge a discharged house battery and eliminate overcharging either battery if the charger is left on for extended periods.

- Revising the DC power wiring to accomplish the above requirements and conform to current ABYC codes.

Battery Replacement

Fortunately, four deep discharge six volt golf cart batteries will just fit in the existing battery box for Mk I boats. These offer the specific characteristics required on a cruising boat, namely to supply house load power for one to three days between charges, repeatedly, over a long life span. Because they are used in large numbers for golf carts, the price is reasonable. However, they should be purchased from a local battery jobber to avoid the traditionally high marine markups and “hazardous material” shipping costs. Check the Internet for more details, availability and dealers.

These six volt batteries must be connected in series-parallel to supply 12 Volts at the capacity required. Trojan brand Model T105 batteries are high quality and readily available in most locations and have become something of an industry leader in capacity, quality and life. They are rated at 225 Amp hours each so the four in a series-parallel arrangement will provide a nominal 12 Volts with 450 Amp hours compared to the 105 Amp hours of the original Group 24 battery.

For later model boats originally equipped with two 4-D batteries, these can be connected in parallel providing only a slightly lower capacity house battery than the four golf cart batteries noted above. If you have a fairly new boat or new batteries, this may be the way to go.

A note is necessary here regarding connecting any high-capacity lead-acid batteries in parallel. It must only be done using batteries of the same type (flooded, gel-cell or AGM). Further, batteries must have the same manufacturer, be the same model and of be essentially the same age and condition. If one battery fails internally, causing a short circuit, and the other is relatively new and fully charged, a high circulating current can occur between the two resulting in acid expulsion and overheating. If both are charged and discharged together as a pair from new, they will age similarly and avoid this problem. Thus paralleling batteries for higher capacity can be done without concern if these conditions are met.

If installing the four golf cart batteries, a plywood base should be made for the existing battery box using ½" marine plywood to provide a solid base for the batteries. When installing them, two should be placed in the battery box and pushed to the stb side of the boat. Then there is space for the other two. Hold-down braces can be made using 1½" x 1½" hardwood. These should be cut so that they fit on top of the batteries and extend under the fiberglass flanges of the settee base. They can be secured with bolts extending through the fiberglass flanges and the hardwood bracing to apply downward force on the tops of the batteries. Be sure to allow access to the filler caps. Paint both base and hold-downs with at least two coats to resist any spilled battery acid. Alternative installation methods have been covered in an earlier Mainsheet Tech Note section.

There is an additional hidden benefit here. Fortunately, the additional weight of the four batteries helps to offset the congenital port list present in all C34s.

Starting battery

A standard automotive or marine starting battery can be used for engine starting, but not a deep-discharge type. Starting batteries are designed to provide high starting current intermittently but will tolerate few deep-discharge cycles. A General Motors type side terminal starting battery is lower in height, fits in tight places and has protected terminals. Since the Universal diesel is small compared to automotive engines, the smallest size battery you can get will be adequate.

A good location is under the aft cabin bed under the forward removable cover since this allows short cable runs and is away from the heat of the engine. However, it could be mounted in other locations as well. If the total cable run (total of positive and negative wires) exceeds 15' it would be best to use #1 cable rather than the #2 shown on the schematic.

Cut a plywood base for the battery and shape two wedges to conform to the hull of the boat to support it. Use fiberglass and resin (West System epoxy is best) to tab the wedges to the hull. Again, paint both the wedges (after they are glassed in) and the base to resist acid. Automotive batteries now generally use bottom clamps for hold-downs and these can be fashioned using wood cleats to engage the flanges provided on the battery.

Alternator & Regulator

All internally regulated automotive and marine alternators have only a “float” battery charging capability. This is accomplished by regulating the alternator output to 13.6-13.9 Volts (depending on temperature). By regulating the voltage to this level, even when charging a deeply discharged deep-cycle battery, the regulator cuts back significantly on the charging current within a few minutes of starting the engine as the battery voltage recovers to this voltage level. The regulator is designed to replace the small amount of energy used for starting and support loads while the engine is running as it is in an automobile. It is not designed to periodically recharge a discharged battery rapidly since this almost never occurs.

For use on a cruising sailboat the alternator must rapidly recharge the house battery. For this it must be configured for an external, processor based three-stage “smart” regulator. The external regulator plugs into the alternator with the two-contact plug supplied with the regulator. These regulators provide a “bulk” charge for rapid recovery of the battery at a high alternator voltage of 14.1-14.3 Volts which maintains the charging current at 30-80 Amps depending upon battery condition. This continues until the battery has recovered to 75-80% capacity. They then cut back to a slightly lower voltage which results in an “acceptance” charging rate of 10-15 Amps, and then to a “float” voltage of 13.5-13.7 Volts which charges the battery at a low amperage rate when it has reached 90-95% capacity. These voltages are for flooded lead-acid batteries but are adjustable for other battery types (gel or AGM).

Both Xantrex and Balmar make excellent three-stage regulators of this type for marine application. They are available from most marine equipment suppliers. It is essential to use a higher capacity alternator when using these three-stage regulators since there is no current limiting control in the system. Current is determined only by the voltage regulation of the regulator, internal resistance of the alternator and battery, and engine speed . Thus with a large, discharged house battery the charging current in the first “bulk” stage can easily be as high as 70-80 amps and the alternator must be able to handle this load.

There are several high capacity alternators available from Balmar and several other suppliers which use external regulators and will fit the rather confined space in the C34 engine compartment. Because of this tight space and the single belt drive, it is necessary to limit the alternator size to 100 Amps maximum and use a “small case” alternator. The Universal engine requires a type 712-912 mount which is a single 2" long foot. If using a Balmar alternator, note that there is a clearance problem with either the stock Universal bracket arm or the one supplied by Balmar and the Balmar fan. This requires relieving the bracket arm with a file to clear the fan.

A lower cost unit of this type is made by Blue Circle Auto Electric in Grand View, Wisconsin based on a Delco small case industrial engine alternator with this type mount and an external regulator. Their ordering reference for a 100 Amp unit which will replace the original Motorola unit on Universal diesel engines without any modifications is M-7102-HD. Price is $175.00 plus $11.55 S&H [as of May 2012 - Stu]. The Blue Circle phone is 888 932-2423.

The alternator and water pump drive belt must be extremely heavy duty to withstand the torque of a high output alternator and a hardware store V-belt will last only hours. Get a high quality, heavy duty belt from an automotive store such as NAPA. A belt with notches on the inside is best as these provide better cooling for the belt. Alignment of the three belt pulleys is also critical with this high a belt load. This must be corrected if the pulleys are at all out of line, even if there were no problems with the stock Motorola alternator. Use a straightedge to check this after mounting the new alternator A #7390 or #7400 belt should fit.

[03/24/2013] - My adjusting bracket broke. Since a new one would have taken two weeks to obtain through the local Universal dealer or Torreson, I had one made locally, a tad thicker, too. I use 7400 3/8" belts on our 100A Blue Circle alternator (using the metric bolts). I found the alternator bottomed out the new bracket and I couldn't get tension. I tried a backup 7390 belt I had, too short. I went to NAPA and found they make a 7395 belt.

Echo Charge or Combiner

Manually or permanently connecting the alternator output to both the house battery and starting battery would defeat the purpose of isolating the starting battery. Use of a diode isolator, which was common practice some years ago, introduces a voltage drop between the alternator and the battery as indicated above. Since the regulator determines the state of charge of the battery by measuring the alternator voltage, this voltage drop (typically 0.7 volts) deceives the regulator and makes the battery charge level appear higher than it really is. Consequently, this will result in chronically undercharged batteries and is incompatible with any three-stage “smart” regulator.

A Battery Combiner (also known by as a Pathmaker) senses the battery voltage and when it is being charged, operates a relay connecting the house battery and starting battery together. When the engine is shut down and the alternator is no longer charging, it opens the relay and isolates the batteries. This overcomes the shortcomings of the isolator. The alternator should always be connected to the house battery and the combiner connects the starting battery only when the alternator is charging.

The Battery Combiner works fairly well in most applications. However, it will tend to overcharge the engine starting battery when using a high current (80 - 100 Amp) alternator and the house battery is discharged and recharged regularly, as it would be on a long cruise or at anchor with periodic engine charging. To avoid this, Xantrex developed an Echo Charge unit which uses a separate solid state regulator instead of a Combiner to charge the starting battery independently of the current and voltage being applied to the house battery.

[Added by Stu 10/21/09] A few years after Jim wrote this article, he noted to me that he had MOVED the Echo Charger connections FROM the 1-2-B switch posts TO the banks themselves. The reason is a simple operational one, and is discussed in this Message Board thread, see Reply #31, [1]. The complete text of that change is included at the end of this article.

This is desirable since the starting battery has only the short-time load of the glow plugs and starter while the house battery is routinely discharged for long periods with the engine shut down. Consequently, the charging requirements for the two batteries are totally different. The Xantrex Echo Charge unit typically limits the charging current for the starting battery to around 15 Amps maximum and cuts it back to near zero as that battery approaches full charge. This is done essentially independently of the state of charge or charging current for the house battery.

Connecting the alternator directly to the house battery is a better arrangement than passing the charging circuit through a battery switch as was done in the stock Catalina wiring for several reasons. Besides the improved charging characteristics covered above, it avoids the problem of opening the charging circuit while charging heavily and damaging the alternator diodes.

For further reading on high output alternators, “smart” regulators, Combiners, Echo Charge units and marine battery charging see West Marine’s “West Advisor®” write-ups in their catalog on these subjects. Also check www.amplepower.com and download their “Ample Power Primer.”

Shore Power Charger

There has been a significant technological improvement in shore power chargers in recent years. Sophisticated voltage control and processor based three-stage charging, as covered above under alternators, have become the standard. This overcomes the tendency of the older and poorly regulated “constant voltage” chargers or ferro-resonant chargers to overcharge the batteries if left on for long periods. The newer chargers recharge discharged house batteries much more quickly while optimizing battery life.

A 20 Amp charger is adequate for use with a four T105 or two D4 house battery bank and a separate starting battery. Since each of the multiple outputs is regulated independently, the charger adjusts for differences in charging current required by the two batteries. It will charge both batteries even with the battery switches off.

Light, compact “switch mode” chargers are available from Xantrex (Truecharge) at reasonable prices. A convenient location for the battery charger on a C34 is on the forward bulkhead of the port cockpit locker (yes, you can get in there if you clear everything out). An additional advantage of these chargers is that they do not have the hum or buzz typical of the older units. Xantrex offers a remote indication panel which may be mounted near the C34 electrical panel.

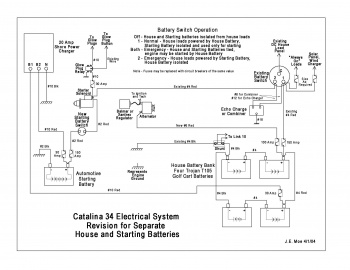

Wiring RevisionsThe schematic diagram shows a wiring scheme for combining the above upgrades with the existing wiring in an older Catalina 34. The four six volt golf cart batteries are shown wired in series-parallel to provide 12 volts. In later boats, the two original equipment D4 batteries may be connected in parallel for the house battery in lieu of the four golf cart batteries shown. Fuses are shown in the battery and charging leads as is now required by the ABYC code. Both the lead to the switch and the lead to the alternator must be independently fused as shown. The shore power battery charger leads must be fused as well but these fuses will generally be 30 Amps maximum so automotive style fuses and in-line fuse-holders may be used. Fuses should be located within the battery box and with the batteries located to stb, there is space on the port side of the battery box for the large fuses. A reasonably priced line of high-amperage fuses is the Blue Seas series #5000 Mega Fuses (#5001 fuse holder). |

|

Though not shown on the wiring diagram, bus bar terminals such as Blue Seas #2106 250 Amp “Maxi Bus” may be used to combine the several leads shown connected to the battery terminals. This is also necessary if you have more than one lead going to the battery negative and are using a Link 10 or similar battery monitor which requires a shunt for current measurement and a single lead to the negative post.

Only one of the existing #4 red leads from the battery box to the switch is needed. This is connected from the positive lead of the battery to position #1 of the existing switch. The other lead may be removed, left in as a spare for an inverter, or connected in parallel with the other lead to reduce voltage drop. The existing #4 black ground lead from the battery negative to the engine is used. While the voltage drop in the original #4 battery leads was excessive for routine engine starting, it is adequate for all house loads and occasional engine starting due to the increased house battery capacity and lower internal resistance.

Ancor brand cables with swaged terminals for jumpers between the six volt batteries are available from many marine stores or cables may be made up as required if you have a proper sized crimper to handle #4 wire and terminals. A new #6 red wire must be run from the battery box to the alternator for charging from the alternator. This is the only new wire from the engine area to the battery box that needs to be run, assuming the shore power charger wiring is already in place.

Most Catalinas used a plastic conduit for the wires from the engine to the battery box and it may be possible to get this wire in the existing conduit. If not, it should be protected with a flexible plastic 1/2" or 3/4" conduit available in the electrical department of Home Depot or similar store. The existing red #4 lead from the starter solenoid to the battery switch is used, but is removed from the common terminal of the switch and connected to position #2 of the switch. Since the starting battery is also connected to the starter solenoid, this wire effectively goes to the starting battery as well and is used both for charging and emergency starting from the house battery bank.

With the revised wiring, position #1 of the battery switch is for normal operation. The switch should be left in this position at all times unless you want to isolate the house battery when the boat is unattended or for emergencies. If the switch is placed in the “Both” position, the starting and house batteries are paralleled or, if the starting battery switch is off, the house battery alone will be connected for engine starting. If the house battery is ever completely discharged, the starting battery may be used in an emergency for lighting, radio, etc. by placing the switch in the #2 position. In this case, the house battery is totally isolated. Obviously, the switch should never be placed in the “Both” or #2 positions except in emergencies as either could result in house loads inadvertently depleting the starting battery. The starting battery is connected directly to the starter solenoid terminal as it is in an automobile.

A fuse and a battery switch are shown in this circuit to protect the wiring and to isolate the battery if desired. The same type fuse as used for the house battery should be located near the battery. The switch should also be located near the battery to minimize the wire run to the starter solenoid. Blue Seas #9006, BEP #700-701 or Hella #87181 switches will handle the starting current, are small and reasonably priced. The starting battery ground cable can be attached to any convenient bolt on the engine block.

If a side terminal automotive battery is selected, good quality standard side terminal automotive battery cables with swaged terminals can be used. Belden brand battery cables are excellent quality and carried by all NAPA stores in various lengths with factory swaged terminals. Ancor brand cables with swaged ring terminals in several lengths are available from West Marine and other marine stores for runs from a marine starting battery with eye terminals and/or runs from fuse block to switch and switch to starter solenoid. These should be used for all the #2 and #4 jumper leads for both batteries if you don’t have access to a large crimper to make up the cables yourself.

As crimped or swaged terminals for #2, #4 and #6 wire are un-insulated, all of these terminals should be sleeved with Ancor brand shrink tubing coated internally with adhesive. This will provide maximum corrosion resistance and battery acid “wicking” up the copper conductors inside the vinyl insulation.

The charging circuits for the shore power charger should be connected independently to both batteries as shown. Shore power chargers with multiple battery outputs provide the required isolation between batteries and independent regulation for each battery. Leads from the positive terminals of the charger to the positive terminals of the batteries should be protected with fuses near the battery in the same manner as the positive power leads. Fuses should be rated at 150% of the charger capacity.

Loads which are “always on,” such as bilge pumps, etc., as well as alternate charging systems, should be connected directly to the house battery. These may be connected either to the #1 terminal of the battery switch or directly to the positive battery terminal and each must be protected with a fuse or circuit breaker rated at 150% of the current rating of the device. If connected directly to the battery, it may be necessary to use a bus bar terminal (as indicated above for the negative battery terminal) to avoid an excessive buildup of connections on the positive battery post.

Glow plug solenoid

Though technically not a part of the overall dc power system upgrade, the schematic shows a solenoid relay for operating the engine glow plugs. If your boat is wired to operate the glow plugs directly from the ignition switch or push-button and is not already equipped with a solenoid relay in this circuit, it would be desirable to include this modification in the general electrical power upgrade. The voltage drop in the wiring harness and glow plug switch or pushbutton as provided on earlier boats significantly reduces glow plug effectivity and can cause hard starting, particularly when it’s cold.

A suitable solenoid relay, Cole Hersee #24106-BP, is available from West Marine. Install it at the rear of the engine, making sure at least one of the mounting flanges is grounded to the engine. Disconnect the wire coming from the Universal harness to the rear glow plug. Connect this to the small terminal on the solenoid relay. Connect a fused #10 lead from the starter solenoid to either large terminal of the solenoid relay and another #10 lead from the other large terminal to the rear glow plug.

Where it typically took 20-50 seconds previously to preheat the glow plugs with a cold engine, it should take only 8-12 seconds to preheat them after the conversion. Current Westerbeke-Universal diesel engines come equipped with this type of solenoid relay. This improvement is well described on the C34 Web site Projects page at [glow plugs].

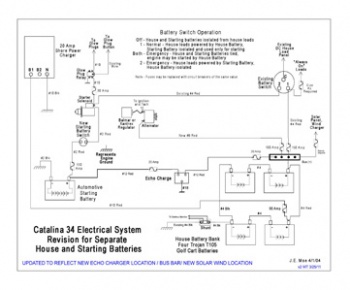

CHANGES TO JIM MOE'S WIRING DIAGRAM - ECHO CHARGERS and WIRING CHANGES TO KEEP THE 1-2-B SWITCH

(from a MB topic discussion) In Reply #11, Item 3, on this topic, I mentioned that Jim Moe had CHANGED his echo charger connections FROM the 1-2-B switch connections TO the bank (+) posts.

This is a VERY IMPORTANT modification.

SEE UPDATED WIRING DIAGRAM

|

Click this link to download the high res version media:UPDATED_CatalinaElectricSystem.jpg

|}

Click this link to download the high res version media:UPDATED_CatalinaElectricSystem.jpg

|}

In a discussion recently on co.com (see: [2]) we discussed this very issue. It is an operational, not electrical design issue. This is a copy of the pertinent ideas from that full thread.

Bob wrote: "It looks to me that if that switch [reserve bank on/off switch] was off the echo charger wouldn't be doing it's job."

I replied: As Jim's wiring diagram is set up, you are completely correct. I spoke with Jim since he published this in 2004, and he noted that based on my suggestion he has moved the echo charger from as shown to the battery (+) posts as recommended by the echo charger manufacturer.

The following is very IMPORTANT to understand: Since his operating concept is to turn the reserve bank switch ON when he gets on the boat and he doesn't leave it plugged in when he's away, what you point out, quite correctly, is not an issue for him if wired this way. Again, you're right: if the reserve bank switch was OFF, and wired this way, the echo charger would NOT charge the reserve bank. Period. If wired to the banks, it wouldn't matter and would always work.

The co.com link also explains how you can change Jim's wiring diagram with two switches to my "preferred" single 1-2-B switch design with just two simple wiring mods. And given this link, there are way more other designs out there, too.

Here's how:

Here's what you CAN DO - based on Jim's diagram ONLY to change from Jim's two switch design to Stu's single 1-2-B switch design:

1. Take the reserve on/off switch and throw it out (or just leave it ON) 2. Conceptually: Run the reserve (+) DIRECTLY to the #2 post of the 1-2-B switch for power TO the switch and run a wire from the output "C" post of the switch to the starter solenoid

To do this you need to do two things: 1) Take what's shown as the "Existing #4 red" between the starter & the #2 post and MOVE it FROM the "2" post TO the "C" post of the 1-2-B switch, and leave it on the starter. This gives you power TO the starter from either bank. It also lets you parallel the banks if your echo charger fails (backup, backup, backup...) 2) Run a new wire from the (+) output of the reserve bank to the #2 post of the switch, without that pesky second on/off switch. Do not run ANYTHING from the reserve bank to the starter solenoid, go only directly to the switch. (The wiring sizes are your choice.)

You're done.

Bob, what this does is make the 1-2-B switch THE controller for the output to the starter from either of the 2 battery banks (and, of course, to the DP).

It also does exactly what I've been suggesting all along - uses the simple 1-2-B switch to control everything. It changes Jim's design to mine!!!

1. The 1-2-B switch is only used for battery bank selection and output to two things; the DP and the starter (the "always on" loads can be left as shown or run directly to the house bank or other switches and fuses - your choice)

2. The alternator output goes to the house bank [nowhere near the switch!!!] with a combiner, echo charger, etc. used to supply the reserve bank. Also see the discussion below about using the 1-2-B switch for that purpose.

Simple, eh?

The downside of "Stu's design" is that engine starting from the house bank can knock electronics off line. That's why some folks prefer having the reserve bank always start the engine.

Your boat, your choice.

For more thoughts on this, see: Alternator Output & Battery Switch Wiring: [3]

Option Summary: Either use Jim's two switch design or my preferred "Keep the 1-2-B Switch arrangement" which is:

1. continue to use the 1-2-B switch

2. AO direct to house bank

3. each bank output to 1-2-B switch

4. C post of switch to distribution panel and starter solenoid

5. either use an echo charger to charge the reserve bank or use the B position on the switch - simple

ABOUT CHANGING YOUR OEM ALTERNATOR

You don't "HAVE TO" upgrade the alternator, because the acceptance of the battery bank will limit the current that can go into them. In most cases the original internal regulator with the stock alternator will provide enough amperage to keep your house bank between the 50% and 85% SOC quite well, albeit somewhat longer than a newer higher output alternator would. Smaller alternator, less charging, longer charging time. If, however, you're a weekend warrior, it'll make little difference. In all cases, though, there is a steadily diminishing law of input power from an alternator alone on a house bank, which is why, unless you have alternate charging sources like solar or wind, you will need to plug into shorepower at least weekly to bring your house bank up to full. Written up in most reliable electrical source books, like Calder.