Galley Counter

Counter Top Replacement Thanks to Capt Al Kindred Spirit #55 for the following counter-top replacement instructions. Remember, these apply to a 1986 C34; more recent models may vary.

Over the years, improvements in galley counters have been made. Can we make old look new? The slow deterioration of the old, around the IceBox...Sink and other areas may require that it be replaced. In my case the Stantion bolts leaked for years letting water drip down the sidewall and under the counter and rotted it away. (Remember I just bought this boat, so it was not my caulking neglect). Now that I have my galley counter out I was going to get a piece of Corian and produce a new counter...to my dismay I can not buy a piece because they will not sell to just anyone. Now I am looking into Cast Polymer, a SYN-MAR Product that is a cast polyester resin and stone fillers. It would be poured around a mold made from my counter top (by the counter shop). It should be less expensive that Corian...I am told.

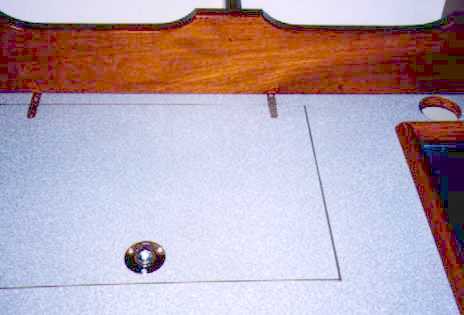

Procedure for Removal of C34 Galley Counter Top (1986) First a description of what the counter is made of. The sink-icebox-stove areas are a one piece fiberglass shell laid into the boat waiting to have a top placed on it. Catalina made a 3/4" plywood top to fit, covered it with Formica and added nice teak trim at all edges except the edge against the starboard wall. It can be removed without removing any of the draw slide built-in units.

Procedure:

Remove all draws from galley area, removing hinge doors around side and front of sink area would be helpful. Disconnect both sink drain hoses at the bottom side of sink. Disconnect hot, cold and foot pump water supply to sink.... Remember it is easier to disconnect lower in the lines instead of up behind the sink. Carefully pry sink up and out. Edges will bend!!!!! NOTHING HOLDS IT BUT CAULK. Shoot the person that sealed it with 5200. If it will not pop out you can wait and take it off, counter and all. SIDE NOTE: #1 While the sink is out is the time to replace the hot water heater. You would have to remove the draw slide unit though.

Next remove the wood dish fiddle that goes across the counter by the icebox and stove. It is held in with five screws, Two through the small bulkhead at the shelf above the settee seat, two in aft cabin bulkhead wall (in aft cabin) (two horiz (counter screws, do these now and you will not have to come back) and two vert (these for dish fiddle)) and one behind stove up into wood dish fiddle. Feel with your fingers till you find the screw hole. Tilt stove forward and it can be reached. Remove dish fiddle and set aside. SIDE NOTE #2: To remove the wood plugs from the bulkhead walls ...take a fine threaded sheetrock screw, cut the head off, put it in your trusty battery drill, aim at the center if the plug and screw it in. When the screw tip hits the head of the ss screw it should (with luck) drive the plug out cleanly. Probe the Philips into the hole, light whack with the hammer till you find the slot and unscrew the fastener. . If the plugs did not come out try this: Cut head off wood or sheet rock screw, insert screw into your drill. Press point of screw into center of wood plug and slowly screw it in with the drill until it hits the head of the SS screw that you are trying to get to. Continue at slow speed to force the plug out on the threads of the screw in the drill. If the plug fully comes out, stop reading and undo your screw. If like 9 out of 10 of mine, the screw in the drill hits the SS screw and just turns, leaving only a hole in the center of the plug but not removing it, go to next step. Plug now has small hole in its center. Making the hole a little larger will make this easier. Use a wood drill bit, 3/16" or1/4" max, drill to head of SS screw....DON'T RUIN HEAD OF SS SCREW! Take an ICE PICK (for wood workers, try an AWL) not a small screwdriver, SLOWLY stick the awl into the plug, chipping the pieces toward the center hole you drilled. NEVER stick the awl in and try to pry the pieces of the plug out.....IT WILL SCAR THE SIDES OF THE PLUG HOLE. Work slow and pieces will fall out. Remove SS screw.

Now it is time to remove the screws that hold the counter top in. It can be done with sink in or out. I recommend, sink OUT. Location of Philips screws: (you must reach up inside the fiberglass shell unit to remove these screws...they are screwed up into the bottom of the counter top.) One center of front of sink One center rear of sink Three portside edge of sink (left of sink for those who are laying with their head somewhere under the sink.) Three right side edge of sink, real close to draw slide unit. Three or four above the draw unit to right of sink One IN ICE BOX, front..stove side...feel around with your fingers till you find it. (never thought to look there.) If you have done all the above, lift the counter behind the stove at the rear aft cabin wall, upward, a light tap upward may free it from the wall. Once high enough to clear the stove, slide it out. Remember if the sink is still in, that end of the counter must be lifted to clear the sink. After removing from the boat and placing on sawhorses, take a scrap block (to protect the wood) and tap all the teak fiddles off from the inside...screws and all. I described above how to remove the plugs and screws. Good job to do home in the basement. Now you have a perfect template to take to your counter top shop and have them reproduce one with your choices of color and material. If you are handy, get a new sheet of 3/4" plywood and new Formica and go to town. Galley Counter Top Replacement Making and Installation Items needed for new top:

4' x 8' exterior grade, good one side plywood. $40 (Watch the number of plys that the plywood is made up of, 7ply is what I used, more is better)

Your choice of Wilson Art / Formica, one sheet 4' x 8' $65

Formica glue, roller, brush and router

Using the old counter for a template, trace out the exact shape on the new plywood. You will notice that four inches of the old counter stick over the new wood. (at rear of stove). To solve this problem, I glued and screwed a four-inch wide piece of clear pine, 12" long to that corner of the new plywood. This way the old top can be traced onto full size wood. Plywood only comes in four-foot widths, unless you want to pay big $. Trace out the sink and ice box openings also.

Now using a skill saw and a saber saw, cut out the outline of the counter and the sink opening. NOT the icebox opening.

Measure in 3 inches all around the icebox opening and cut out this smaller opening. More on this in a moment.

Using a belt sander, sand all the edges to the template lines. Remember that all the edges are covered with teak so a little off is ok.

Locate the edge that butts to the hull (back of stove side!) and with the belt sander grind this surface back at a 45-degree angle. This will give the counter the relief that it needs to get a good fit.

NOTE: A modification that I made to the top was adding 2 inches in width in back of the stove. You must do this before you cut out your new counter. It will involve cutting the finish teak to the left of the stove 2 inches shorter before re-installing.

TIME TO TAKE IT TO THE BOAT AND SEE HOW WELL IT FITS!!! Is the stove too close to the new counter if you added on? Remember you have to have room for the teak. In the small hole that you cut out at the ice box...stick your hand in with a pencil and trace the out line of the ice box on the back of the counter top.

TAKE BACK HOME! Turn the counter upside down so you can see the outline of the icebox opening you drew. Draw straight lines 3/8 inch bigger than these lines all around. This will give you a 3/8 lip all around the box for the lid to sit in.

Neatly, using a skill saw and finishing the corners with a saber saw, cut out on this line. Make marks with a pencil so you know which way to put it back when we use it for a cover. After the edges of the icebox opening are covered in Formica and routed, (I will cover this in a moment) I glue 3/8 storm door rubber insulation to the back of the box opening all around. The insulation has a 3/8 round portion and a 1/4 inch flat part for fastening. This flat area is what gets glued to the back of the opening, with the round sticking into the box opening as a seal. When you look down from the top you only see the round insulation that the lid sits on. The only disadvantage is that you will have to cut it off with a knife if you ever need to replace it. The other method would be to glue 3/8 wide insulation to the box lip after the counter is installed. Lets do the Formica before tackling the lid.

Laminating Formica is not all that hard. Using the counter as a template, trace it on to the back of the Formica, counter top upside down also. You will have to seam the Formica somewhere in back of the stove; again 4-foot wide material was cheaper. Rough cut the Formica at least 1 inch bigger that your outline to leave room for error and placement when gluing. Rough cut the small piece for the back of the stove and belt sand the seam till it fit nicely. Also cut 4-1 inch wide pieces to perfectly fit the inside lengths of the icebox opening. Set up a large work area so that you have the counter top face up and the Formica upside down. Brush contact cement on the edges around the ice box opening, let dry....all wood surfaces get two coats of glue. Re-coat opening and coat pieces that will be laminated there. Let dry to touch and place all around opening. Tap with rubber mallet to insure good bonding. Use belt sander to finish these strips around the opening flush with the counter top. Flip top over and sand flush with bottom also. Now we are ready to laminate the top.

Make sure all surfaces are clean. Coat counter top with contact cement. Roller made for this works best. Brush is difficult but ok.

Let dry. Coat top a second time and also coat back of Formica. Place long CLEAN sticks on top of the counter so that the Formica can be laid on top of the counter WITHOUT touching it. 3/8 inch round dowels, 3 feet long are perfect for this, but almost anything small and long will due, including something metal. Line up the Formica on top of the counter....starting from one end, pull out the spacer and touch the Formica to the top. Once touched it will not come loose. Work your way one spacer at a time, rubbing out any air bubbles as you go. No spacers needed for the small piece behind the stove, just push the seams together first as you lay the piece down. Take you router with a ball bearing Formica bit and cut out around all edges. REMEMBER that the rear edge is a 45 angle so router will not work on that face. Use the belt sander there. Poke hole at icebox and sink and route around those edges.

Sand edges of Formica smooth around the ice box opening using 120 sandpaper on a small wooden block.

Refasten teak fiddles all around counter and plug screw holes.

Teak plug re-installation: Before installing the piece again, Use a 3/8" plug recess tool to clean the hole for the new screw and plug. (Just like if you were doing a new screw hole). Once you have replaced the SS screws, purchase 3/8" teak plugs. Place wood glue around the plug, line up the grain and lightly tap, till the wood plug hits the SS screw. Wipe off any glue and let dry over night. Take a very sharp wood chisel and tap the top of the plug off about 1/8" above the finish surface so that you can see which way the grain is breaking on the plug. It will break off like a ski slope. The low side is the side you should be finishing with the chisel to the finish surface...a little at a time from the low side. Sand flush and oil or varnish.

ICEBOX LID: I used the same 3/4 ply that came from the opening that I cut. WHAT TO DO WITH THE SMALLER HOLE IN THE CENTER?????? Fill it with 3/4 inch solid foam!!!!!! We need more insulation. Important to remember here that the lid needs Formica all around its edges. Some sanding before Formica may be needed to get a good fit. Also if you are using this cut out that the inside edges have to be recessed for the insulation or the cover will sit to high. Cover the top and edges with Formica screw on the inside foam insulation and you have your lid. Cutting down the old 1/2 inch lid and recovering with Formica will also do. Another change I made here is to hinge the top. The only thing I do not like about this is it hits the upper shelf not allowing us total access to the opening of the icebox. Note: Using hinges with spring loaded pins or 2 piece hinges will alleviate this problem.

INSTALLATION: Place the counter top on a few dabs of silicone and screw up from underneath as before. I did not like being on my head so much so I put the sink in, outlined it in light pencil and removed it again. I noticed that the sink overlaps well over an inch. On that overlap I did my screws from the top down. Drill/countersink 8 screws spaced around sink. Replace the two screws thru the aft cabin bulkhead. Place the teak dish holder on the counter behind the stove, mark with pencil its width and remove.

Drill/countersink 2 screws under this teak to fasten counter. Fasten teak dish holder in place as before Put lots of silicone around the sink, set sink in place, plug drain fill with water to hold sink firmly in place till dry.