Difference between revisions of "Clean and Lube your winches"

| Line 32: | Line 32: | ||

== Cleaning == | == Cleaning == | ||

| − | Lots of options for solvents. I used mineral spirits which seemed to work well but the old hardened grease still needed to be brushed out after soaking. Other options | + | Lots of options for solvents. I used mineral spirits which seemed to work well but the old hardened grease still needed to be brushed out after soaking. Other options include boiling the parts with an orange cleaner type solvent. Messy job anyway you go at it... (lots of old towels and gloves that don't dissolve in the solvent - ie. latex or similar) |

* Wipe or brush off any excess grease. | * Wipe or brush off any excess grease. | ||

Revision as of 08:56, 25 January 2010

Note: This page is for Lewmar winches, mostly the two speed primary winches but usable for any winch.

Looking through the Lewmar Service Manual it may seem like there are lots of parts than may never go back together but a nice thing about our Lewmar winches is they come apart surprisingly easy and only go back together one way.

Servicing your winches (at least somewhat) regularly reduces the chance of having them break or jam up when they are most needed. In general it's a much more messy job than technically difficult.

Contents

Tools and Parts Needed

- Lewmar or similar waterproof grease

- A few drops of light weight oil

- Lots of old towels, rags, paper towels.

- Solvent (Kerosene, Mineral Spirits, Paint Thinner, WD40, Orange degreaser, etc)

- Small (tooth) brush

- Small tub/bowl to soak parts

- Replacement Pawl Springs (usually replaced)

- Replacement Pawls (depending on age)

- Box with hole in bottom (optional)

- Screw Driver

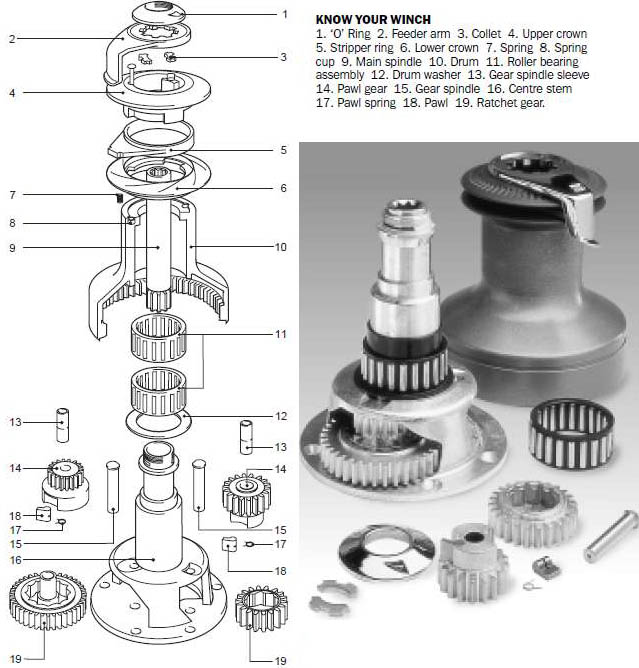

Assembly Diagram

Disassembling

- Depending on your year/model there are either four screws or a spin on ring on top of the winch.

- Once that is off, the feeder arm is removed and small inserts (collets) are slid out and the entire drum lifts off. Be careful as there two sets of bearings and at least one of them will likely stay inside the drum so watch they don't slip out and bounce overboard. (this is where the box can help)

- Then there are two identical pins (gear spindles) on the base that lift out and all 4 gears slide out. Only thing left is the center shaft which also lifts out.

Cleaning

Lots of options for solvents. I used mineral spirits which seemed to work well but the old hardened grease still needed to be brushed out after soaking. Other options include boiling the parts with an orange cleaner type solvent. Messy job anyway you go at it... (lots of old towels and gloves that don't dissolve in the solvent - ie. latex or similar)

- Wipe or brush off any excess grease.

- Soak the parts in solvent and wipe the base & inside of the drum down as well.

- Brush inside the teeth of the gears as well as the bearings.

- Make sure the 'inside' of the gears where the pawls touch are clean.

- Remove all solvent: some suggest using soap (rinse/dry) or using liquid paraffin

Lubricating

- Do Not Over Lubricate, thin grease coating only.

I watched a Lewmar demo at a boat show and they stressed that while making sure everything is coated in grease, including the base but just a very thin coat to make it sticky but no more. About what would be left behind after a light wipe with a cloth. Extra grease just attracts more dirt, gums things up and makes it harder to clean next time. Using a brush helps coat the gears evenly. I also applied a thin coat to the gear teeth inside the drum as well as where the main bearings will roll against. I used the Lewmar brand grease though I'm sure any winch grease would work or any water proof grease though results may very.

The only other lubricant required is a few drops of a lightweight oil for the pawls & springs as grease in the pawls will likely gum up and cause a failure. The pawls are the most important part of the winch and are about the only part that will fail under normal use so make sure they are very clean and not worn down.

Assembling

- First assemble the pawls & springs and mate the two sets of gears.

- Slide the large gears in the large opening of the base, larger gear down, insert pin

- Slide the other set of gears in the other opening, larger gear up this time, insert pin

- Slide the large plastic washer/shim over the base

- Slide a bearing set, spacer and the other bearing set over the center stem of the base.

- Finally there's also one trick to getting things back together. Remember to lift the center shaft a quarter inch or so to get the collets to slide back in place.