Difference between revisions of "Whale Gusher Galley Mk3 Service Kit"

Dancrosswis (talk | contribs) |

Dancrosswis (talk | contribs) |

||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | '''by Dan Cross, ''Ennui Went #159''''' | ||

| + | |||

=Intro= | =Intro= | ||

| Line 35: | Line 37: | ||

##Remove valve seat small O-ring and discard. | ##Remove valve seat small O-ring and discard. | ||

##Remove valve stems and valves and discard. The valve stems can be pulled out with pliers and pushed in from the outside of the outflow valve. | ##Remove valve stems and valves and discard. The valve stems can be pulled out with pliers and pushed in from the outside of the outflow valve. | ||

| − | |||

==Reassembly== | ==Reassembly== | ||

| Line 47: | Line 48: | ||

##Install new valve and valve stem to inside of valve body. Valve’s concave side will face outward to meet the valve body. I propped the valve and valve stem on the intake valve body nipple, see Figure 8, to get the valve/stem assembly into valve body. Needle nose pliers may also work. | ##Install new valve and valve stem to inside of valve body. Valve’s concave side will face outward to meet the valve body. I propped the valve and valve stem on the intake valve body nipple, see Figure 8, to get the valve/stem assembly into valve body. Needle nose pliers may also work. | ||

##Install new valve and valve stem to remaining valve seat. Again, the valve’s concave surface faces the concave surface of valve seat. | ##Install new valve and valve stem to remaining valve seat. Again, the valve’s concave surface faces the concave surface of valve seat. | ||

| − | ##Reseat valve seat. Place new small O-ring on valve seat. Apply dish soap to O-ring. Press seat into valve body with the valve on the inside of the valve body. | + | ##Reseat valve seat. Place new small O-ring on valve seat. Apply dish soap to O-ring. Press seat into valve body with the valve on the inside of the valve body. |

#'''Reassemble front diaphragm.''' First, a note on diaphragm orientation. The diaphragms are identical. Either can be used for the front or back. Each diaphragm is installed with its concave surface facing outward toward its cover. Just in case your diaphragm is inverted, the raised inner and out rims are on the <u>convex</u> side of the diaphragm. | #'''Reassemble front diaphragm.''' First, a note on diaphragm orientation. The diaphragms are identical. Either can be used for the front or back. Each diaphragm is installed with its concave surface facing outward toward its cover. Just in case your diaphragm is inverted, the raised inner and out rims are on the <u>convex</u> side of the diaphragm. | ||

##Insert front piston plate into new front diaphragm. Concave side of the diaphragm will face towards the front cover. | ##Insert front piston plate into new front diaphragm. Concave side of the diaphragm will face towards the front cover. | ||

| Line 60: | Line 61: | ||

##Insert the spring in the front piston plate. See Figure 12. | ##Insert the spring in the front piston plate. See Figure 12. | ||

##Reattach the front cover. Again, the front cover will be subject to spring force. First insert the front cover screws into the front cover. Line up the cover to the body and valve assemblies. Press down on the body against your work surface and screw down the screws. The front cover will pull down onto the valve assemblies as the screws are tightened. See Figure 13. | ##Reattach the front cover. Again, the front cover will be subject to spring force. First insert the front cover screws into the front cover. Line up the cover to the body and valve assemblies. Press down on the body against your work surface and screw down the screws. The front cover will pull down onto the valve assemblies as the screws are tightened. See Figure 13. | ||

| + | #'''Reinstall the four screws at pump lever.''' | ||

| + | |||

| + | ==Observations== | ||

| + | |||

| + | I was impressed by the quality and design of these pumps. I can see why they have remained unchanged for 30 years. The only damage I found looks to be related to anti-freeze. I found a pink “high water” line in the pump attached to the refrigerator box. I suspect the line was created by anti-freeze left in the pump each winter. The lower intake valves in this pump were deformed. I don’t know for certain, but suspect that the damage is from the anti-freeze. The pump still worked, but it seemed to take a lot of strokes to clear the refrigerator box. | ||

| + | |||

| + | ===Changing Orientations=== | ||

| + | '''Right to Left Hand.''' My pumps are right handed. The front and rear covers appear to be mirror images. I suspect the pump hand can be changed from right to left by simply swapping the front and rear covers. | ||

| + | |||

| + | '''Intake and Outflow.''' The intake on each of my pumps is at the bottom. It appears that the intakes can be changed from bottom to top by simply switching the positions of the intake and outflow valve assemblies. | ||

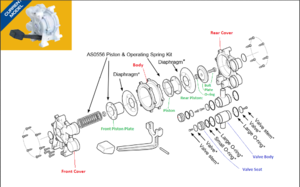

|valign="top"|[[File:Pump_Exploded_View.png|thumb|left|Figure 1]] | |valign="top"|[[File:Pump_Exploded_View.png|thumb|left|Figure 1]] | ||

| Line 74: | Line 85: | ||

image:Valve_Rebuild.JPG|Figure 11 | image:Valve_Rebuild.JPG|Figure 11 | ||

image:Front_Spring_Reassembly.JPG|Figure 12 | image:Front_Spring_Reassembly.JPG|Figure 12 | ||

| + | image:Compressing_Front_Cover.JPG|Figure 13 | ||

| + | |} | ||

Latest revision as of 16:55, 12 October 2016

by Dan Cross, Ennui Went #159

Contents

Intro

The following are the steps I developed when installing service kits for my two Whale Gusher Galley Mk 3 foot pumps. These pumps have been manufactured since 1984, so I suspect they will be found on most all of our boats. The service kit is part number AK0553. It is widely available. I bought my kits on eBay. They looked like old stock, but the parts were fine. I have serviced two pumps, so I have limited experience. The following procedures worked for me. But, they may not all be correct (please mention any needed corrections) and certainly are not the sole way to accomplish this task.

Naming Parts

|

I found a pump exploded view with names for most of the kit parts. I could not find a view which names each pump part. So, I made up some part names to help with my description. My inventions are listed below and shown in Figure 1:

Disassembly

ReassemblySee the Observations at end of this article to change pump from right to left hand or to change the valve intake position from bottom to top.

ObservationsI was impressed by the quality and design of these pumps. I can see why they have remained unchanged for 30 years. The only damage I found looks to be related to anti-freeze. I found a pink “high water” line in the pump attached to the refrigerator box. I suspect the line was created by anti-freeze left in the pump each winter. The lower intake valves in this pump were deformed. I don’t know for certain, but suspect that the damage is from the anti-freeze. The pump still worked, but it seemed to take a lot of strokes to clear the refrigerator box. Changing OrientationsRight to Left Hand. My pumps are right handed. The front and rear covers appear to be mirror images. I suspect the pump hand can be changed from right to left by simply swapping the front and rear covers. Intake and Outflow. The intake on each of my pumps is at the bottom. It appears that the intakes can be changed from bottom to top by simply switching the positions of the intake and outflow valve assemblies. |

<gallery perrow=2 caption="Click on thumbnails to enlarge"> image:Remove_Lever_Screws.JPG|Figure 2 image:Remove_Rear_Cover.JPG|Figure 3 image:Pry_Off_Diaphragm.JPG|Figure 4 image:Front_Cover_Removed.JPG|Figure 5 image:Tapping_Out_Valve_Seat.JPG|Figure 6 image:Valve_Orientation.JPG|Figure 7 image:Installling_valve.JPG|Figure 8 image:Front_Reassembly.JPG|Figure 9 image:Rear_Reassembly.JPG|Figure 10 image:Valve_Rebuild.JPG|Figure 11 image:Front_Spring_Reassembly.JPG|Figure 12 image:Compressing_Front_Cover.JPG|Figure 13 |