Tom

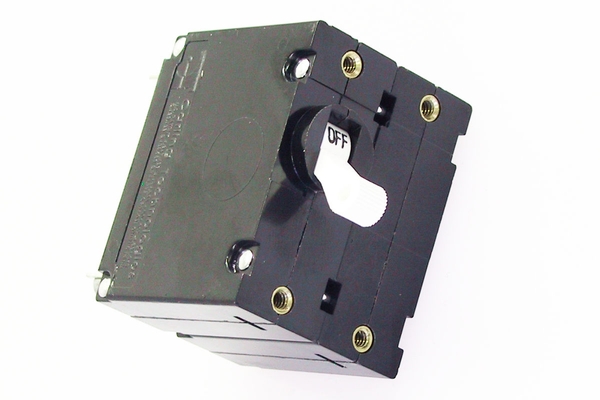

Here's a reason why it's key for owners to post pics when they have a problem -- the breaker on your panel is not like the one that I linked to and is not a safe breaker.

It should be 2-pole, not single-pole, and therefore should be replaced with one of the type CD shows, or a double-handle-toggled breaker.

You didn't answer which white/black wires on the AC Terminal strip in your first picture are from the Smart Plug. So does the shore power feed run thru the 30-amp breaker or does it go to the term strip?

The reason as others say that a breaker was later added at the transom is that ABYC requires the Main Breaker to be within 10 feet of the boatside inlet.

Without parsing what work you explained that you did to find the ground fault, generally:

It could be a failed GFIC receptacle. That is common. So start there and disconnect the circuit for the port/starboard receptacles.

Or the water heater possibly leaking current, so try that circuit next.

Then the charger circuit.

As you work thru it, reconnect whatever you disconnected before progressing to the next circuit.

Here's a reason why it's key for owners to post pics when they have a problem -- the breaker on your panel is not like the one that I linked to and is not a safe breaker.

It should be 2-pole, not single-pole, and therefore should be replaced with one of the type CD shows, or a double-handle-toggled breaker.

You didn't answer which white/black wires on the AC Terminal strip in your first picture are from the Smart Plug. So does the shore power feed run thru the 30-amp breaker or does it go to the term strip?

The reason as others say that a breaker was later added at the transom is that ABYC requires the Main Breaker to be within 10 feet of the boatside inlet.

Without parsing what work you explained that you did to find the ground fault, generally:

- Start with all connected (I presume that with the breaker off, there is no ground fault trip?)

- Systematically start disconnecting circuits to isolate which one is causing the trip.

- Then systematically isolate to locate what item ON THE tripped circuit is causing the trip.

It could be a failed GFIC receptacle. That is common. So start there and disconnect the circuit for the port/starboard receptacles.

Or the water heater possibly leaking current, so try that circuit next.

Then the charger circuit.

As you work thru it, reconnect whatever you disconnected before progressing to the next circuit.